Foster + Partners has created a prototype for a general-purpose prototype face visor, which is suitable for cleaning and reuse. By using its simple cutting machine, the studio is able to cut and assemble components for 1,000 visor masks per day. According to the studio, it is much faster than producing masks with 3D-printed alternatives.

All images courtesy of Foster + Partners

Designed by a team of industrial designers, model makers, architects and analysts at Foster + Partners, the prototype is specifically aimed to go into mass production to help fight the coronavirus (Covid-19).

The studio has also shared the design templates and material specifications as an open-source design asset - with instructions here and the file for the digital flatbed cutter (.dwg) downloadable on its website.

"This is to encourage both designers, and in particular large-scale manufacturers, to investigate the potential of digital and laser cutting machines as an alternative to 3D printing technology," said Foster + Partners.

All images courtesy of Foster + Partners

Three components

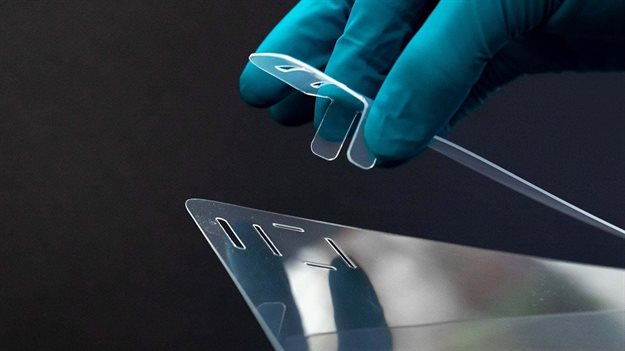

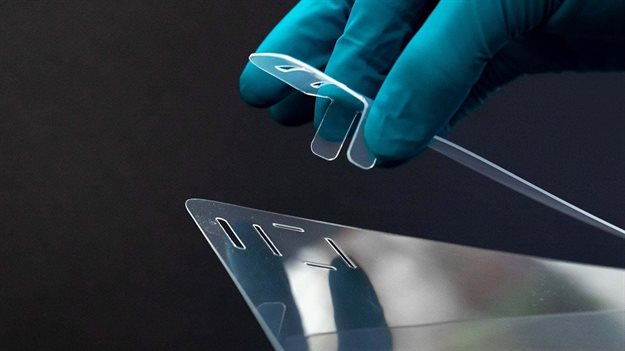

As the studio explains, the prototype visor is made from three components: a visor made from 0.5mm optically clear PETG, an interlocking soft PP headband, and a surgical silicone rubber head strap that ties the two together.

These are all cut on the practice’s digital flatbed cutter. Each visor can be cut from sheets in under 30 seconds and the elements can be assembled in under a minute.

"With our single cutting machine, we were able to cut and assemble components for 1,000 visor masks in a day, representing a reduction of days in the time taken to produce 3D-printed alternatives," added the firm.

All images courtesy of Foster + Partners

The visors can be produced and assembled or flat-packed and distributed in large quantities in a short span of time. An important advantage is that the visor can be easily disassembled, cleaned, sanitised and reused, addressing the growing shortage of raw materials for visor production.

"We are now delivering these prototype visors to a number of London hospitals where they are being tested. We are also exploring means of getting the design approved for mass production and use by health workers."

All images courtesy of Foster + Partners

All images courtesy of Foster + Partners

Foster + Partners also explained that "the studio has no prior expertise in the design and manufacture of personal protective equipment (PPE) and therefore this design has neither been made by reference to any specific regulations nor subject to any formal testing regime."

"That any user of the design shall assume all responsibility for developing the design in conformity with regulatory and testing requirements of any markets it intends to make the visor available in," the firm added.

Article originally published on World Architecture Community.